A structured way to plan work,

understand and operate technology, and communicate effectively

Many

people apply the Input-Process-Output

model without being aware of it. Using the model deliberately can be very

helpful for:

∑

planning work

∑ understanding and operating technology

∑

communicating effectively

∑

structuring training

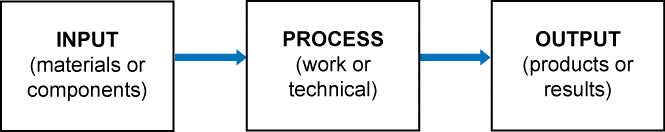

Work

and technical processes control changes

to achieve the desired results. The following diagram shows the three stages of

the change process:

As

a generality, work and technical processes are used to change materials to

produce a desired result (e.g., reshape metal, bake a cake, assemble an

appliance, separate hydrocarbons into various components, create a chemical

change). Generally, the quality of the output product remains constant.

Sometimes a change in the quality of the input materials creates the need to

adjust the work or technical process to achieve the desired output.

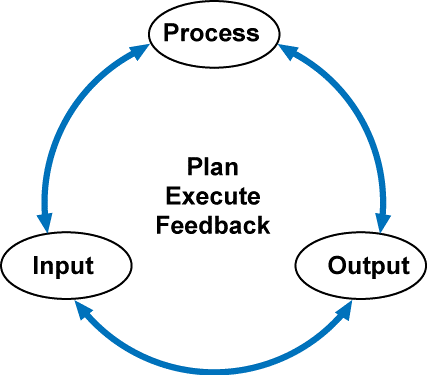

Input,

process, and output can be thought of as a continuous loop.

One

can start at any point in the loop and go in either direction to plan, execute,

and get feedback. Starting with output is a natural starting point because the

objective or result must be understood before considering how to achieve those

results. After having used the strategy to initially think though the work, a

different starting point and sequence can be used to get a better understanding

of a specific concern. The goal is to continually refine and improve safety,

efficiency, and cost-effectiveness in achieving the desired results.

Within a given set of roles and responsibilities, one must identify the variables

(e.g., quantity, composition, shape, pressure, temperature) that must be monitored,

controlled, or responded to achieve the desirable output. For example:

∑

input

variables define the quality of the materials used

∑

process

variables of personal action, tools, and equipment

that create the change

∑

output variables define the

quality of the product or results

Each variable must be measurable either using numerical units and ratios or

non-numerical units. Examples of numerical units and ratios are 3600

revolutions per minute, 130 degrees Fahrenheit, 325 centimeters long, 2 parts

water to 5 parts of pulp. Examples of non-numerical measurements are the water

appears clear and put just enough force on the board to get a clean cut but not

so much to overload the motor.

To

control the technology and make decisions, one needs to know the

characteristics of the variables as shown in the matrix below.

|

VARIABLE

|

Static

|

Dynamic

|

|

Controllable

|

static

&

controllable

|

dynamic

&

controllable

|

|

Non-controllable

|

static

&

non-controllable

|

dynamic

&

non-controllable

|

Knowing

whether an equipment or material variable can change and whether or not the

change can be controlled is very helpful in doing jobs well and responding

effectively to changes. One must also understand the cause(s) or reason(s) for

changes and how changes can impact PEMEO (defined in a previous post). Asking

questions about the variables can be very useful for performing work and

understanding and controlling technology effectively.

Using

the input-process-output model is an excellent way to organize ideas to

communicate effectively as a trainer or supervisor. The model can help to

organize content in training documents such as self-instructional modules. The input-process-output

model can provide an overview in the introduction. For example, when explaining

what a piece of equipment does, a brief statement such as the following could

be used:

∑

Trees are fed into a chipper which reduces the trees to chips

to produce mulch (input-process-output)

∑

Mulch is produced by making chips out of trees (output-process-input)

∑

The chipper slices trees into chips to produce mulch (process-input-output)

The

detailed content can then be organized in the same order presented in the

introduction.

The

books EquipThink and MatThink provide detailed information

about thinking strategies to plan work, do work, use technology and materials effectively,

efficiently, and safely, and to make effective decisions. Using thinking

strategies contributes to exemplary employee performance which, in turn, can

improve job and corporate performance. The books use an educational design and

have exercises to apply the thinking to the world of work.

Do

you use the input-process-output model when thinking about work or operating

and maintaining technology? Do you think this model is a useful thinking

strategy in your personal life? Do you think that the input-process-output

model is useful for communicating how technology works and to structure

training?

Gordon

Shand is President of HDC Human Development Consultants Ltd. He has 35 years of

experience designing and developing educational and training programs that have

excellent practical value and contribute to the customerís business success. www.hdc.ca